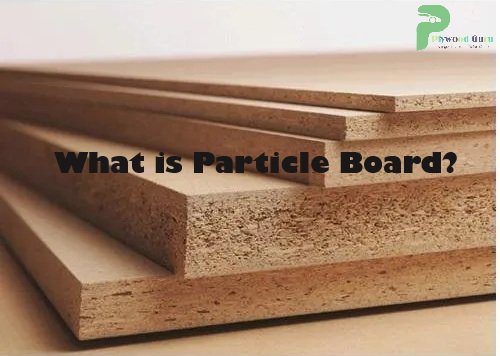

Particle Board: An Affordable and Versatile Wood-Based Material

Particle board, also known as chipboard or low-density fiberboard, is a widely used wood-based material composed of wood particles, such as sawdust, wood shavings, and other small wood fragments. The particles are bonded together using a synthetic resin, typically urea-formaldehyde, under high heat and pressure.

In this Article

- What Is Particle Board?

- What is a Particle board used for?

- What is the Particle Board Price?

- Difference between Particle Board vs Plywood

Composition and Manufacturing Process

The process of creating Particle Board involves transforming these wood particles into a flat, dense sheet. During manufacturing, the particles are mixed with the resin and then formed into a mat. This mat is subjected to intense pressure, causing the particles to bond and adhere to each other. The high temperature helps cure the resin, resulting in a sturdy and rigid board.

Advantages of Particle Board

Particle board offers several advantages, making it a popular choice in various applications:

- Cost-Effectiveness: One of the primary advantages of particle board is its affordability. Compared to solid wood or other engineered wood products, particle board provides a budget-friendly option for manufacturers and consumers.

- Versatility: Particle board is highly versatile and can be used for a wide range of applications. It can be easily cut into different shapes and sizes, making it suitable for furniture, cabinetry, and interior construction.

- Consistency: The manufacturing process of particle board ensures a uniform composition, reducing the variations commonly found in natural wood. This consistency allows for predictable and reliable results in production.

- Utilization of Wood Waste: Particle board is often made from wood by-products and waste, contributing to the efficient utilization of resources and minimizing environmental impact.

Disadvantages and Considerations

While particle board has its advantages, there are some considerations to keep in mind:

- Durability: Particle board is generally less durable than solid wood, especially when exposed to moisture. It may swell or warp if not adequately protected.

- Environmental Impact: Some particle boards may contain formaldehyde, a substance known to emit volatile organic compounds (VOCs). However, advancements in manufacturing have led to low-emission and eco-friendly options.

Applications of Particle Board

Particle board finds extensive use in various industries:

- Furniture Manufacturing: Particle board is a common material in the production of furniture, including shelves, tables, cabinets, and bed frames. Its cost-effectiveness makes it a preferred choice for mass-produced and ready-to-assemble furniture.

- Construction and Interior Design: In construction, particle board is used for interior applications such as wall paneling, subflooring, and underlayment. It is also employed in interior design projects for creating decorative elements.

- Packaging: Particle board is utilized in the production of packaging materials, providing a stable and cost-efficient solution for crates and pallets.

Particle board is an engineered wood product that offers several advantages. Firstly, it is cost-effective compared to other alternatives like plywood or solid wood. This makes it an attractive choice for budget-conscious consumers. Additionally, particle board is easy to work with, as it can be easily cut, drilled, and shaped to fit various design requirements.

When it comes to furniture, particle board is widely used for its affordability. Particle board furniture is commonly found in households and offices, ranging from cabinets and shelves to tables and desks. Its smooth and consistent surface allows for easy application of laminates, veneers, or paints, further enhancing its aesthetic appeal.

What is the difference between Particle Board vs Plywood?

The key differences between particle board and plywood in terms of composition, strength, durability, cost, weight, usage, resistance to moisture, application, and sustainability.

| Criteria | Particle Board | Plywood |

|---|---|---|

| Composition | Wood particles bonded with synthetic resin | Layers of wood veneer glued together |

| Strength | Less strong compared to plywood | Generally stronger, especially in shear strength |

| Durability | Prone to damage from moisture, less durable | More resistant to moisture, higher durability |

| Cost | More cost-effective | Typically more expensive than particle board |

| Weight | Lighter | Heavier |

| Usage | Interior applications, furniture | Versatile, used for furniture, construction |

| Resistance to Moisture | Susceptible to swelling and warping | Better resistance to moisture |

| Application | Suitable for dry areas, limited load-bearing | Versatile, suitable for various applications |

| Sustainability | Environmental impact due to resins | Can be sustainable depending on sourcing |

Standard Size & Thickness of Particle Board Available in Indian Market

In the Indian market, particle boards are commonly available in standard sizes such as 8′ x 4′, 9′ x 6′, and 6′ x 4′. The usual thickness options include 9mm, 12mm, 18mm, and sometimes 25mm. These dimensions offer versatility for applications in construction, furniture production, and interior design.

| Standard Thickness | Standard Sizes (ft) | Length | Width |

|---|---|---|---|

| 25 mm | 9’ × 6’ | 9 feet | 6 feet |

| 18 mm | 8’ × 6’ | 8 feet | 6 feet |

| 17 mm | 6’ × 4’ | 6 feet | 4 feet |

| 15 mm | 9’ × 3’ | 9 feet | 3 feet |

| 11 mm & 12 mm | 8’ × 3’ | 8 feet | 3 feet |

| 09 mm | 6’ × 3’ | 6 feet | 3 feet |

What is the Particle Board Price?

The price of particle board depends on several factors, including the thickness, quality, and the company brand. Thicker boards tend to be more expensive due to the increased amount of raw materials used. Moreover, the addition of pre-laminated surfaces can also affect the price, as it eliminates the need for additional finishing processes. The price of particle board typically falls in the range of *₹ 35 to *₹ 50 per square foot, positioning it as one of the most cost-effective choices when compared to alternative materials. It’s important to note that these prices are approximate and subject to change.

*For the latest and more accurate pricing details, it is recommended to consult with a designer or relevant industry professional. Prices may vary based on factors such as brand, quality, and market fluctuations.

Also Read: Best Plywood in India for Furniture

FAQs

- Is particle board as durable as solid wood?

- Particle board is generally less durable than solid wood, especially when exposed to moisture.

- What are the environmental concerns associated with particle board?

- Some particle boards may contain formaldehyde, contributing to indoor air pollution. However, eco-friendly options with recycled materials are becoming more prevalent.

- Can particle board furniture be customized?

- Yes, particle board furniture can be customized in terms of design, finish, and dimensions.

- How does the price of particle board compare to plywood?

- Particle board is typically more affordable than plywood, making it a budget-friendly choice.

- Is pre-laminated particle board a better option for furniture?

- Pre-laminated particle board offers enhanced aesthetics and durability, making it a popular choice for furniture.

Particle board company in India

Explore top-quality particle boards by Elite Particle Boards manufacturers in India and Gujarat. Trusted supplier for durable and affordable boards.