📢 Importance of Ram Area Pressure Setting:

The correct hot press ram pressure is main role for plywood manufacturing. If the pressure is too low, plywood may delaminate. If it’s too high, panel thickness down. That’s why accurate pressure calculation is very important for plywood hot pressing.

✅ Plywood Hot Press Ram Area: Key Roles

✔ Uniform Pressure – Ensures even bonding of veneers.

✔ Accurate Thickness – Maintains precise panel dimensions.

✔ Strong Adhesion – Enhances glue bonding for durability.

✔ Quality Control – Prevents defects & delamination.

✔ Optimal Pressure Setting – Prevents delamination & thickness reduction.

🔍 In this blog I will explain how to check the hot press ram area pressure step by step! ✅

🔢 Ram Area Calculation Method (15 Daylight Hot Press)

📌 Given Data:

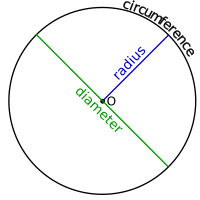

🔄 Circumference: 62.8 cm

📏 Step 1: Calculate Diameter (D)

➡️ D = 62.8 / 3.141 = 20 cm

📐 Step 2: Calculate Radius (R)

➡️ R = 20 / 2 = 10 cm

🟡 Step 3: Calculate Ram Area

➡️ 3.141 × 10 × 10 = 314.1 cm²

🔧 Step 4: Calculate Total Ram Area for 8 Rams

➡️ 314.1 × 8 = 2512.8 cm²

📊 Dial Pressure Calculation

📝 Formula:

📌 Given Data:

📏 Ply Area: 127 cm × 251 cm = 31877 cm²

⚖️ Specific Pressure: 11 kg

🔧 Ram Area: 2512.8 cm²

📉 Calculation:

➡️ Dial Pressure = 139.7 kg/cm²

⚠️ Maximum Dial Pressure: 300 kg/cm²

📈 Specific Pressure Calculation

📝 Formula:

📌 Given Data:

🔧 Ram Area: 2512.8 cm²

📉 Dial Pressure: 300 kg/cm²

📏 Ply Area: 31877 cm²

📊 Calculation:

➡️ Specific Pressure = 23.64 kg/cm²

⚠️ Maximum Specific Pressure: 23.64 kg/cm²